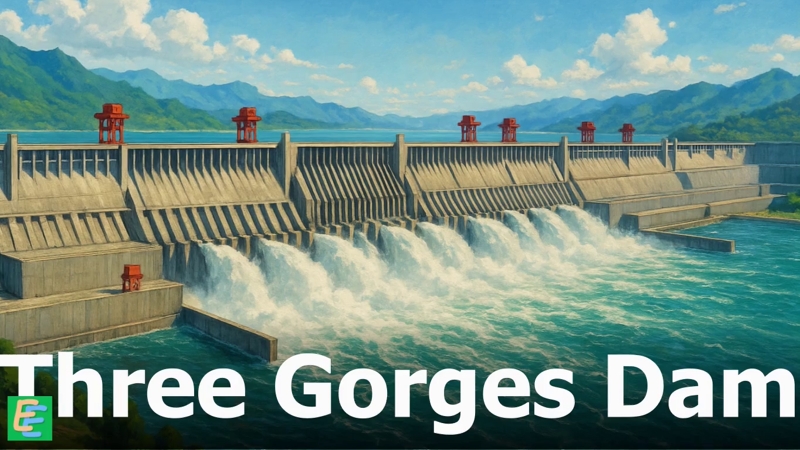

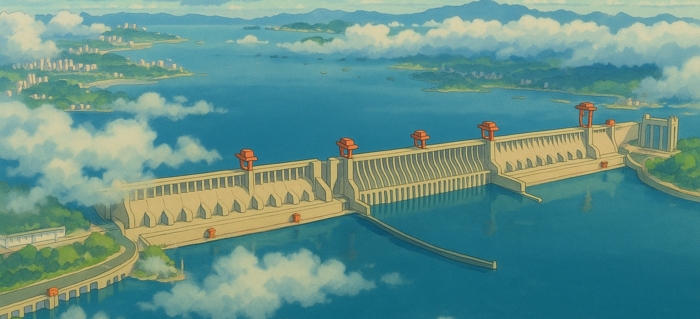

Engineers built a dam so massive… it increased the length of the day by slowing down the Earth’s rotation. It is so powerful that it can produce the electricity equivalent to that of 15 nuclear power plants.

Sounds like science fiction?

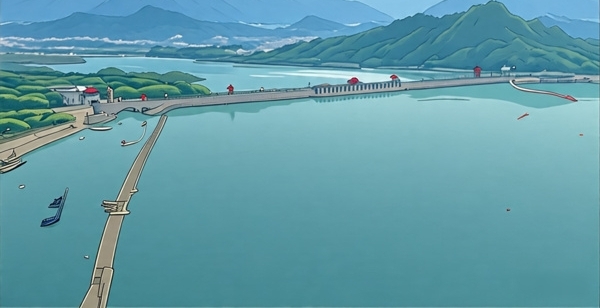

It’s a reality. Let me introduce you to the Three Gorges Dam — the largest hydroelectric power station in the world, built across China’s mighty Yangtze River.

The Yangtze is the longest river in Eurasia — and the third longest on Earth. It begins high in the glaciers of the Tibetan Plateau, then winds eastward through mountains, valleys, megacities — across southwestern, central, and eastern China — before emptying into the East China Sea near Shanghai. Its basin supports nearly one-third of China’s population — making it a lifeline for agriculture, transportation, industry and daily survival.

The Yangtze is a majestic river but sometimes, it turns dangerous. It collects enormous amounts of water from its vast drainage area and seasonal monsoon rains. During periods of intense and prolonged rainfall, the river swells and overflows — creating devastating floods. Floods that have wiped out villages, destroyed cities — and taken millions of lives across centuries.

Such floods are very frequent in this area — around 1 major flood every 10 years.

Recognizing the need to harness the power of the Yangtze River and mitigate its destructive potential, many ideas to construct a dam were proposed as early as 1910s.

But on such a vast and powerful river, the very first challenge was pinpointing the perfect location. It wasn’t simply a matter of picking a spot on the map. Experts spent years studying the river, the terrain, and the underlying geology to find a location stable enough — and strong enough — to support a structure of this scale.

After all the searching, they finally found the spot — where the river narrowed, slowed slightly, and flowed over solid bedrock. The place was Sandouping, in China’s Hubei province. It is very close to the iconic Three Gorges region— where the Yangtze flows through three steep, narrow gorges in a row.

For those unfamiliar, a Gorge is a narrow valley with steep, rocky walls. These are formed by erosive activity of the river, cutting through the landscape over a long period of time.

Now, building a dam means stopping the river from flowing forward. It creates a reservoir — a huge lake that builds up behind the dam and raises the water level.

Just around Sandouping alone, there were over a thousand villages and towns— and hundreds of priceless archaeological sites. All of them would be drowned if a dam was built there.

It was a difficult choice to make. Even within the government, not everyone agreed. But recognizing the potential benefits of flood control, energy generation, and improved navigation, in 1992 the Chinese government gave the green light to one of the most ambitious engineering projects in history.

The construction of the Three Gorges Dam officially began in 1994. But the first phase wasn’t about machines or blueprints — it was about people. Thousands were moved to safer ground. Entire towns were rebuilt to house the millions who had to leave their homes — displaced by the rising waters of the future reservoir.

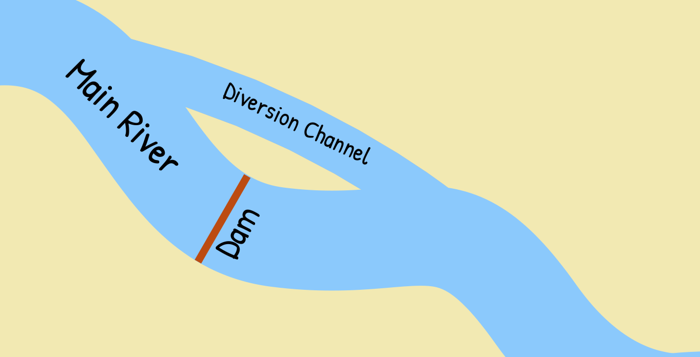

Then, the actual construction challenges began. Typically, when engineers build a dam, they first divert the river — digging a new channel to guide the water away from the construction site and rejoining it downstream.

But Yangtze is no small river. It carries an enormous volume of water — and diverting all of it would’ve been risky, expensive, and could’ve created even bigger, unforeseen problems.

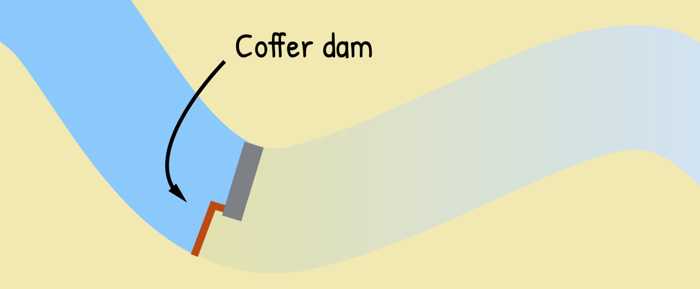

So the engineers came up with a smarter plan. Instead of diverting the entire river, they built what’s called a Cofferdam.

A Cofferdam is a temporary barrier which may be wall or even a dam that is used to block the water.

In case of Yangtze, they didn’t block the whole river, just a part of it. A cofferdam was built on the left bank of the river, allowing the river to continue flowing on the right side.

To construct this, they dumped huge amount of earth and rock in the river. That gave them dry ground inside the cofferdam, where construction on the left section of the dam could begin.

The dam itself was divided into three parts — and the middle and left sections were built first.

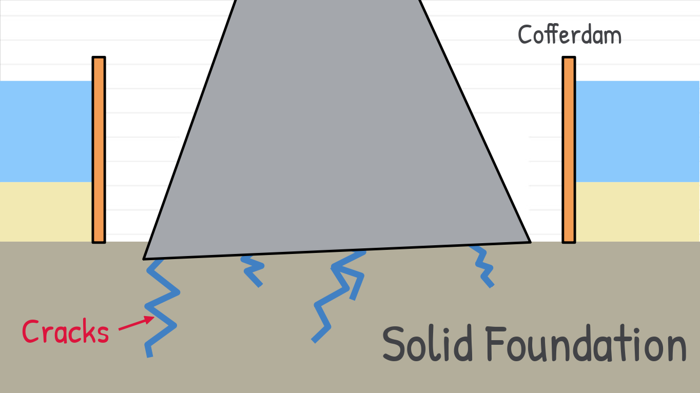

They needed a solid foundation — something strong enough to support the enormous weight of the dam. So, they began excavating the riverbed until they found the bedrock.

But the bedrock they found wasn’t exactly perfect; it was fractured — full of tiny cracks running through it. That was a serious problem. Because water could seep through those cracks, slowly eroding the rock and eventually making the foundation weak and unstable. Also a fractured bedrock foundation might not settle uniformly under the immense weight of the dam causing it to tilt.

To fix this, engineers used a process called Grouting. In grouting, they inject liquid cement into the cracks under high pressure. This sealed the fractures, strengthened the rock and created a solid, watertight base for the dam to rest on.

With a solid foundation in place, it was now time to build the dam structure by pouring concrete. The dam they were constructing was on an entirely different scale. It required millions of cubic meters of concrete — more than what you’d need to build a two-lane highway stretching across all of China.

The problem with concreting such a massive structure is that, as the concrete hardens, it releases heat — a lot of heat. This heat can cause the concrete to crack.

This happens because the outer layers of concrete, being exposed to the ambient air, cool faster than the inner core, which retains heat longer. As the core remains hot, it expands, while the cooler outer layers try to shrink. This generates stress in the concrete, and when this stress becomes too great, the concrete cracks.

And cracks, even small ones, can weaken a structure like this over time.

To deal with this problem, the engineers implemented a series of sophisticated measures.

1. They pre-cooled the aggregates and other materials at special cooling stations — and used chilled water to prepare the concrete mix.

2. They sprayed water and created a misty environment around the concreting areas, especially during the hot summers. This helped block direct sunlight and kept the surface temperature under control.

3. Instead of dumping all the concrete at once, they divided the dam into smaller sections or blocks, like a giant grid. They poured one block at a time, giving each section time to cool and settle before the next one was added. Think of it as building a giant Lego structure.

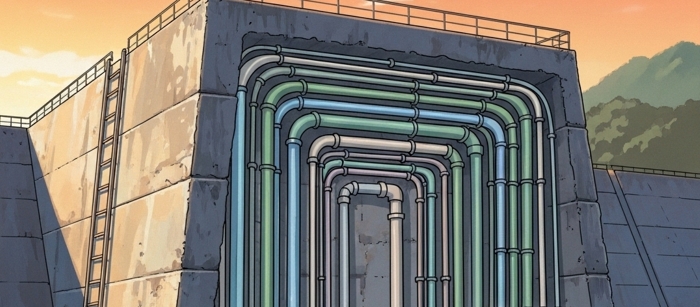

4. To cool the concrete while hardening, they installed cooling pipes inside the concrete blocks. Cold water was circulated through these pipes to absorb and carry away the heat from the curing concrete.

Using all these — and many other — cooling strategies, they completed the entire left side of the dam. Once it was strong enough to hold back the Yangtze, they excavated back the cofferdam material and it was time to face the next challenge: the right side — third section of the dam.

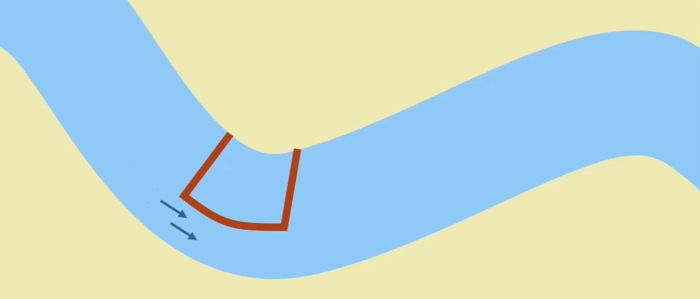

On the right side, they dumped heavy rocks and earth into the river, raising the riverbed. This time, the new cofferdam had to be stronger. Because this new cofferdam would completely block the river flow, the water level would rise, exerting immense pressure on the cofferdam. So this time, it wasn’t just earth and rock. It was reinforced with steel and concrete — built to take the full force of the Yangtze.

Also, since it appears that Yangtze couldn’t go any further, the question arises, where does all that water go?

The answer lies in the heart of the dam itself. In the middle section of the dam, engineers had already built a series of escape channels called Spillways.

These weren’t just holes in the dam; they were carefully designed and constructed pathways for the water to flow out of the dam. So, as the water level rose behind the dam, it flowed out through those spillways — controlled, steady, and harmless, continuing its journey downstream.

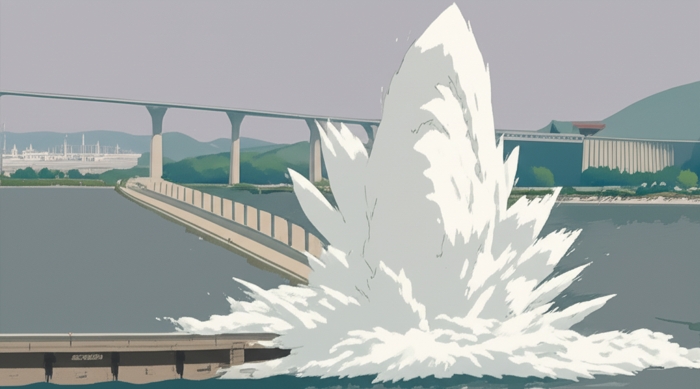

This allowed engineers to proceed with the construction of the right section of the dam. And when the construction was completed there was only one thing remained to do, dismantling the cofferdam. It had done its job, but now, it had to go. And it wasn’t something they could just dismantle easily. It was too strong. Reinforced with concrete itself. So, Instead, they turned to a more dramatic solution: a controlled demolition. They blew it up carefully, in a series of timed blasts using dynamite.

With that, the Three Gorges Dam, stretching over two kilometers (2,309 meters) in length and reaching a height of 185 meters, stood ready to fulfill its intended purpose. In fact, it was already doing so… by holding back the Yangtze and protecting millions downstream from devastating floods.

But this project wasn’t just about taming a river. It was driven by even bigger vision.

The reservoir created behind this colossal dam holds around 40 cubic kilometers (10 trillion gallons) of water. This is so much water that a NASA scientist calculated, this raised mass of water actually increased the length of day by 0.06 microseconds. It also changed the shape of the earth and even shifted the position of the poles by about two centimeters (0.8 inch).

All this stored water has the potential to generate massive amounts of clean hydroelectric power. Engineers installed 32 turbines — each capable of generating 700 megawatts — plus two smaller 50 MW units.

Altogether, that gives the dam a total installed capacity of 22.5 gigawatts making it the largest hydroelectric power plant in the world.

The Yangtze River has been one of China’s busiest shipping routes for centuries. So when engineers built the dam, they knew it couldn’t become a barrier and cut off this crucial artery of trade.

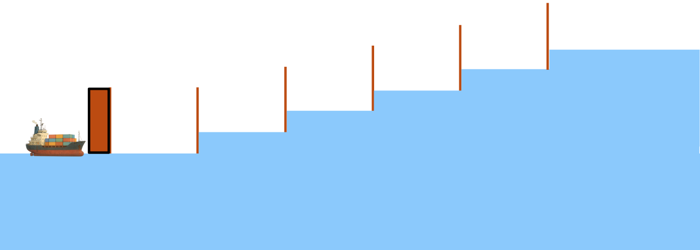

So, they came up with a brilliant solution — a Ship Lock System.

It is a giant staircase for ships. It consists of a series of five massive chambers, each capable of raising or lowering vessels step by step.

Here’s how it works:

A ship enters the first chamber, the gates behind it close. The water level in the chamber is raised or dropped to match the water level of the next chamber. Once aligned, the gates ahead open and the ship moves forward into the next chamber.

This process repeats through all five chambers, allowing ships to pass through the full height of the dam. This whole process takes around four to five hours.

But for smaller vessels, like passenger cruise ships, they engineered an even more remarkable solution: they also built a giant elevator, that literally lifts the ship the 200 m height of the dam in under 40 minutes.

There are also plans of building a railway track near the Dam that would facilitate the movement of goods from downstream to upstream and vice versa, offering another efficient mode of transportation in this vital economic corridor.

The Three Gorges Dam is a modern wonder of the world. The Chinese government considers the project a source of national pride.

It has become a landmark — attracting tourists from around the world who come to see the scale, the story, and the sheer ambition behind it. It stands as a testament to what can be accomplished through vision, perseverance, and engineering excellence.