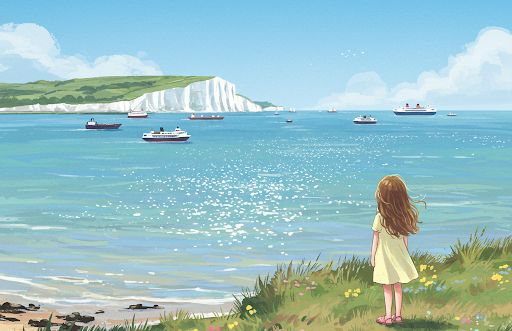

On a clear day, if you stand near the waters at Cap Gris Nez (pronounced kap gree neh) in France, you can actually spot the coastline of England with your own eyes — those famous White Cliffs of Dover, standing bright against the horizon. You’ll see ships and ferries crossing the Channel, just like they’ve done for centuries.

But hidden right beneath those calm waters lies one of humanity’s greatest engineering achievements — a marvel you can’t see, but one that changed Europe forever. A tunnel, carved deep beneath the seabed, linking two nations that had always been separated by the sea.

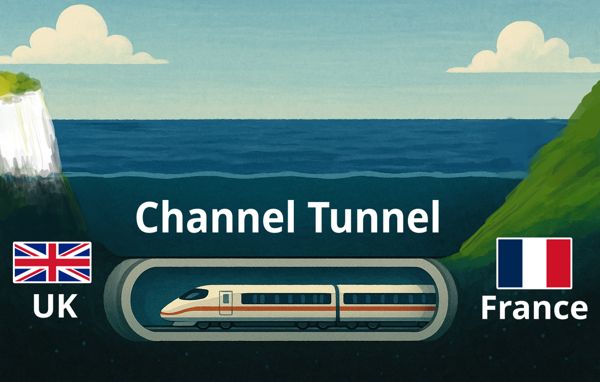

This is the Channel Tunnel — an undersea railway tunnel that stretches over 50 kilometers, which is more than 31 miles. It is one of the most ambitious construction projects the world has ever seen.

But how do you even build a tunnel under the sea? And why did anyone think it was a good idea in the first place? Let’s dive into the incredible story behind the making of the Channel Tunnel.

Great Britain is part of the European continent — but it’s an island, and it’s not physically connected to the mainland. The stretch of water between Britain and the rest of Europe is called the English Channel. And for centuries, that Channel served as a natural barrier — protecting Britain from invasions, wars, and, well… from the rest of Europe.

The Channel kept Britain safe, but it also kept it isolated. Trade was slower. Travel was complicated. Crossing over meant getting on a ship or ferry, and in more advanced days, even planes.

It wasn’t all that bad, but every time you wanted to visit the other side, or move goods across the Channel, you had to check the weather, the tides, and the time. Because sometimes, the sea could turn stormy — and suddenly, it wasn’t safe to cross at all.

So it’s really no surprise that people started dreaming about a permanent connection — a bridge, or maybe even a tunnel.

In fact, ideas for a Channel Tunnel go way back — all the way to the early 1800s. Engineers and visionaries proposed all kinds of wild ideas: a road tunnel for horse-drawn coaches with artificial islands to swap horses, a railway tunnel, even a giant suspension bridge stretching across the full Channel.

But the truth is… not everyone in Britain was excited about being ‘connected’ to Europe — or to France in particular. Many saw it as a clear invitation for an enemy army to walk right up to their doorstep. They feared a connection link could be used to launch a surprise attack.

For a long time, that fear kept killing every serious plan. Dreamers kept dreaming, but governments kept saying no.

But over time, the world changed. Britain and France had fought side by side through two World Wars. Also, attacks from the ground became less relevant with the airplanes ruling the sky. That old fear of being invaded through a tunnel? It didn’t seem so scary anymore.

And the idea of connection started to feel like an opportunity — not a threat.

After centuries of saying yes and no to the tunnel, it finally got approval from both sides, and submissions for designs of the connection link were invited. The proposals on the table were — a giant suspension bridge, a road tunnel, a railway tunnel and even combinations of those!

They chose to go for a railway tunnel under the sea.

Why???

The English Channel is one of the busiest shipping lanes in the world. Massive cargo ships, ferries, and military vessels cross it every single day. Building a bridge would’ve either blocked the shipping lanes… or forced engineers to build it insanely high to let ships pass underneath.

Plus, in stormy weather, those giant bridge spans would be super vulnerable to winds and waves. Which totally defeated the whole point of building a safer, faster, all-weather connection.

So, a tunnel seemed like a better idea. But… should it be a road tunnel or a railway tunnel?

Well, a road tunnel this long had some serious problems.

First, it requires a proper ventilation system. Cars and trucks produce exhaust, and in a short tunnel, that’s not a big deal. But in a tunnel this long, you need a way to constantly suck out toxic fumes and pump in fresh air.

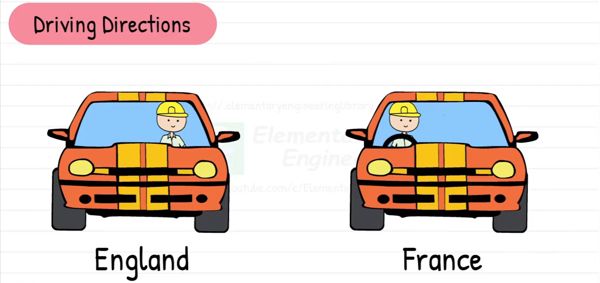

Then, there was the issue of driving directions. Cars drive to the left side of the road in England and on the right in France. This could cause major confusion for drivers in the tunnel and potentially lead to accidents.

And then, there was another weird problem, the human brain. When a person drives on a long and monotonous road with no scenery or break in the view, the driver almost get hypnotized by the road. It is called Highway Hypnosis or Driver mesmerization. In this state their mind wanders or zones out, and they continue to drive, but without full conscious awareness. It is dangerous.

A railway tunnel, on the other hand, solved most of these problems beautifully.

Trains produce far less exhaust, making it easier to manage air quality. Plus, trains run on fixed tracks, so there’s no risk of drivers getting confused or disoriented.

Another big advantage is efficiency. Trains can carry a lot more people and goods than cars, making the tunnel a high-capacity, high-speed link between Britain and France. This means faster travel times and reduced congestion.

And finally, safety. Railway systems are generally safer than road systems, with fewer accidents and better emergency protocols. In a tunnel, this means a more reliable and secure way to travel.

So, the choice was made. A railway tunnel under the English Channel.

But choosing the idea was the easy part. Actually building it? That turned out to be one of the most difficult engineering challenges the modern world had ever seen. Because remember — this wasn’t just digging a hole through a mountain or under a city. They were trying to dig under the sea. A living, moving, pressurized body of water — sitting right on top of them. One small mistake… and millions of tons of seawater could come crashing down, flooding the tunnel, drowning everything.

So how did they do it?

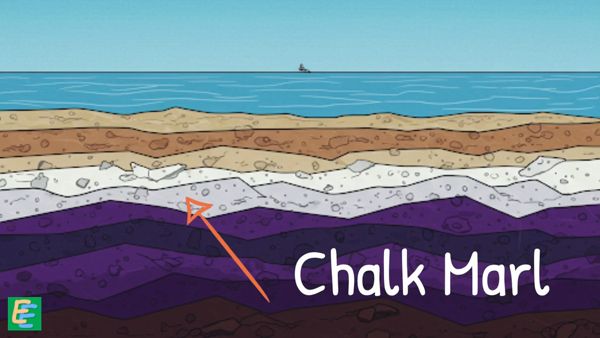

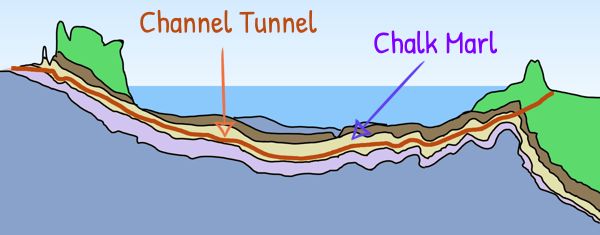

Well, Tunneling is a precise science. You can’t just dig anywhere you like. You need right kind of ground — stable, predictable, and dry enough to work with. And luckily, under the English Channel, they found exactly that: a special layer of chalk marl.

Chalk marl is a type of rock that’s a mix of chalk and marl. Chalk is white limestone made mostly of tiny marine fossils, and it’s soft. Marl, on the other hand, is a clay-rich material that is loose, breakable, and crumbles easily.

Chalk Marl is not pure hard rock like granite, and it’s not loose sand or soft clay either — it’s somewhere in between. Think of it as a slightly sticky, compact, soft rock—firm enough to hold its shape but soft enough to cut through without too much trouble. Even better, it naturally seals itself a little when wet, thanks to the clay, which helps keep water out.

But even with the perfect ground beneath them, digging under the English Channel was nowhere near easy.

The layer wasn’t perfectly uniform — there were pockets of water, loose sand, unstable rock, and fault lines. Any of these could cause a catastrophe.

So what did they do?

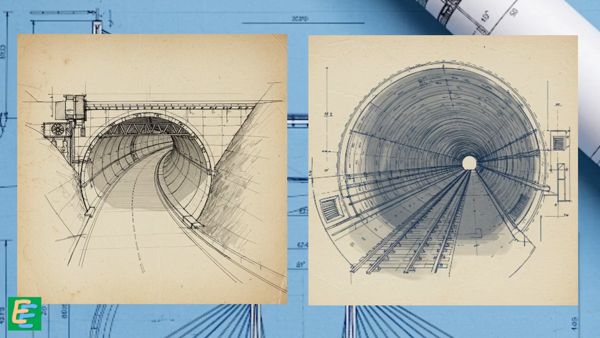

That’s where the real heroes of the story come in: The Tunnel Boring Machines — or TBMs.

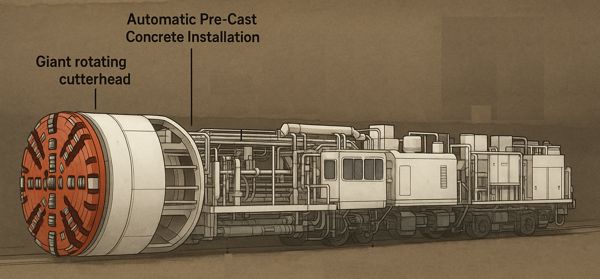

These massive machines were built specifically to excavate tunnels. Think of them as underground factories on wheels.

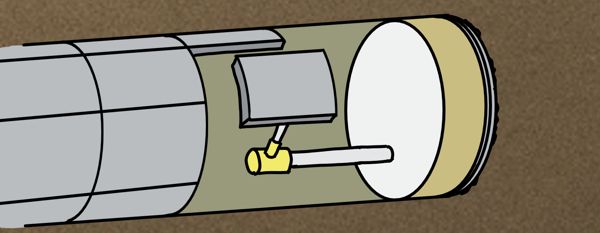

At the front, a giant rotating cutterhead bore through the chalk marl. Right behind it, the machine automatically installed concrete wall segments to support the tunnel as it move forward.

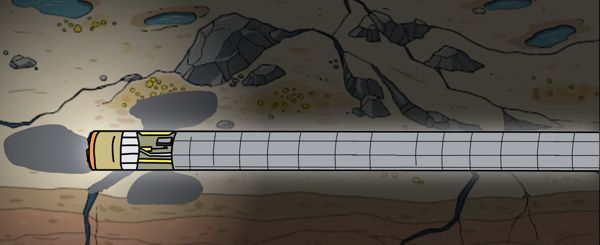

These TBMs were enormous—250 to 300 feet long (75 to 90 meters), with cutting heads about 9 meters ( or 29 feet) in diameter. It’s like a giant mechanical earthworm, digging, eating, and building the tunnel all at once.

Though TBMs had been used in other projects before, for the Channel Tunnel, engineers built some of the biggest and most advanced TBMs ever made up to that point. They custom-designed these giants to handle the unique challenges of tunneling deep under the seabed, through the tricky chalk marl, and under massive water pressure.

The front cutterhead kept steady pressure against the ground, so if they hit a messy patch of loose soil or water, it wouldn’t just rush in. To stabilize these areas, they could inject special grout—kind of like liquid cement—to quickly seal and strengthen the ground, providing immediate support and preventing collapses.

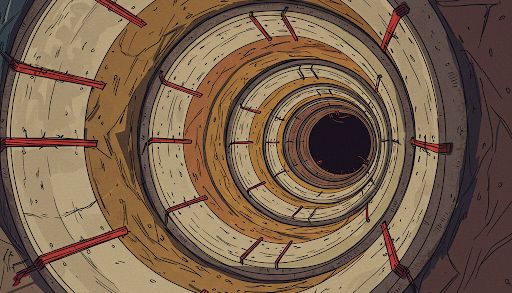

Another clever thing about TBMs: they don’t just dig, they build as they moved forward. They installed precast concrete segments to line the tunnel walls, forming a full ring behind the machine. These rings were essential to provide structural support to the tunnel under the immense pressure from the sea and the surrounding ground.

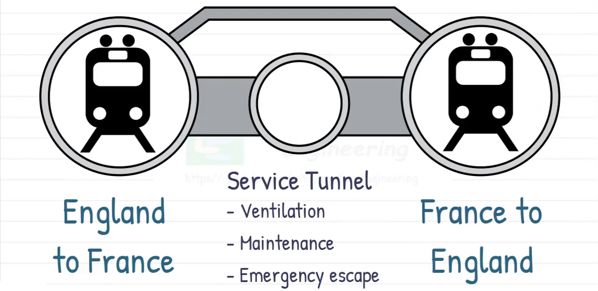

Okay, tunneling is insanely hard. But wait — they were not building just one tunnel… they had to build three! That was the Design plan.

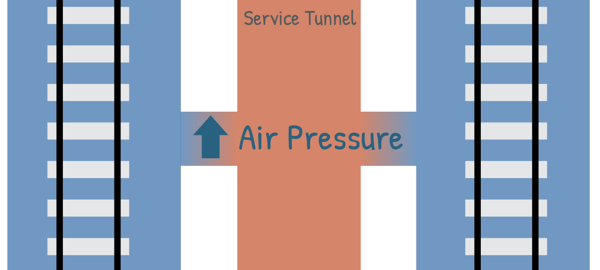

One tunnel for trains heading from England to France. One tunnel for trains coming back from France to England. And a third, smaller service tunnel in between — for ventilation, maintenance, and emergency escape routes.

They used 11 of these massive TBMs, and they bore from both British and French sides.

And after three relentless years of boring through the chalk, inch by inch, a historic moment arrived. The two teams met in the middle of the English Channel, deep under the sea. Two men from opposite sides shook hands through a tiny hole in the rock — sealing a connection that would change history forever.

They met perfectly under the sea, with an alignment error of just a few inches — not feet, not meters — after digging more than 30 miles without seeing each other.

Over a distance that long, even a tiny mistake in angle — say, just 0.1 degrees — could cause the tunnels to miss each other by hundreds of feet.

It is so incredible because there was no GPS under the seabed, no real-time radar. Even the ground conditions on the British side were completely different from the French side and because of that TBMs used on both sides were very different from each other — custom built for different geological conditions.

And on top of all that, the tunnel isn’t just a straight horizontal line. It’s full of gentle curves and little ups and downs along its length. That zig-zaggy path wasn’t random — it was a strategic choice. This way, engineers could avoid fault lines and unstable ground, while making sure the tunnel stayed inside the safe chalk marl layer as much as possible.

After all the boring, digging, and careful lining, the tunnels were finally ready to install railway tracks.

Both of the main tunnels were fitted with rails. Now, the idea of using conventional ballasted track — you know, the classic rails sitting on crushed stones — was ruled out pretty quickly. Maintenance would’ve been a nightmare down there, and it just wouldn’t give the kind of stability and precision they needed.

So instead, they went with something called Low Vibration Track, or LVT. It’s a special system where the rails are basically locked in place using just gravity and friction. What exactly LVT is and how it works — well, that’s a story for another post.

Engineers even thought about the maintenance process. They built two tunnel junctions, or ‘crossovers.’ These let trains switch between tunnels if needed and allow full maintenance of the tunnel, section by section, without having to shut down the entire operation.

Oh, and fun fact: those two crossovers? They’re actually the largest artificial undersea caverns ever built.

They installed a 25 kV overhead line to power the electric trains. All tunnel services run on electricity, shared equally from English and French sources — but in case of emergency, the tunnel can be powered solely from either England or France.

They built massive ventilation plants on both sides of the Channel. These maintain higher air pressure in the service tunnel than in the rail tunnels, so that in the event of a fire, smoke doesn’t enter the service tunnel and block evacuation or support efforts.

In addition to all that, the crews installed everything that makes a railway actually work — fire protection, communication lines, and thousands of sensors and emergency systems inside the tunnels. Basically, they turned three long, dark tubes into a fully functional high-speed railway under the ocean.

Before opening it to the world, there was one last, critical step: Testing. Every inch of the tunnels — the tracks, the signals, the sensors, the ventilation, the power supply, the emergency systems — was tested, re-tested, and stress-tested with empty train runs, simulated fires, power cuts, and full tunnel evacuations to make sure everything worked perfectly.

Finally, on May 6, 1994, the tunnel was officially opened. It was a moment of pure celebration — not just for Britain and France, but for engineering itself. The Channel Tunnel was voted one of the Seven Wonders of the Modern World’ by the American Society of Civil Engineers.

Today, the Channel Tunnel is a vital, everyday link between Britain and Europe. It carries high-speed passenger trains racing between London, Paris, and Brussels. It carries heavy freight trains transporting goods and cargo across the continent. And it even carries entire cars, trucks, and buses on special shuttle trains.

The Channel Tunnel is a marvel of engineering — a tunnel that once thought impossible, a dream delayed for nearly two centuries, was now a roaring reality.