There’s a place in India where trains glide across the sky — not on clouds, but on a bridge so high, even helicopter pilots look up to it.

High in the remote Himalayas, where the mighty Chenab River carves its way through ancient mountains, stands this engineering marvel that defies imagination.

This is the Chenab Rail Bridge – the world’s highest railway ARCH bridge.

Built over two decades, this isn’t just a bridge — it’s a quiet triumph of patience, precision, and purpose in one of the toughest terrains on Earth. And it is the story of challenges no one had ever faced before — and solutions no one had imagined, until this bridge was brought to life.

Kashmir.

A land of snow-capped peaks that kiss the sky, ancient rivers that carve through breathtaking valleys, and serene lakes that reflect skies painted in every imaginable hue.

For centuries, poets have called it paradise. And when you see it with your own eyes…

it’s easy to see why.

Nestled in the northernmost corner of India and cradled by the Himalayas, Kashmir is a place of stunning natural beauty — almost otherworldly.

But also incredibly remote.

And that’s where the problem begins.

For years, the only way to reach the Kashmir Valley from the rest of India was by road. A long, winding highway that climbs through tough terrain — and in winters, often disappears under thick layers of snow.

When the weather closes in, the region gets cut off. Supplies slow down. So do lives.

For a long time, connecting the beautiful, yet geographically isolated, Kashmir Valley to the rest of India by an all-weather railway was a crucial national goal.

This isn’t just about travel; it’s about connecting people, enabling trade, and ensuring year-round access for communities sheltered deep in these mountains.

But for decades, that idea seemed almost impossible.

Because the Himalayas aren’t just mountains — they’re massive walls of rock, deep gorges, unpredictable landslides, and endless snow.

But in 2002, Indian Railways took on the challenge.

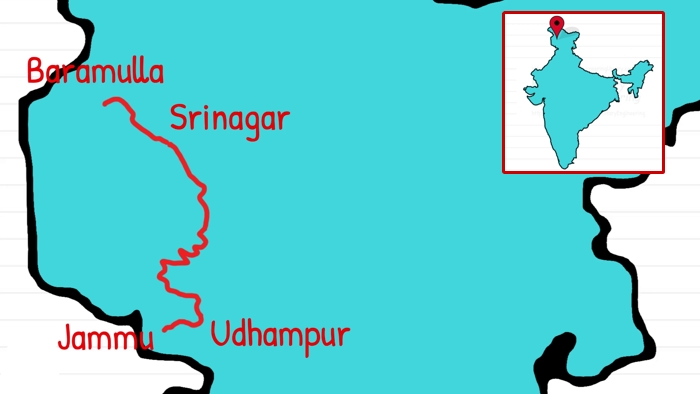

They launched one of the most ambitious railway projects in the country’s history: the Udhampur–Srinagar–Baramulla Rail Link — better known as the USBRL.

The goal was clear: build a railway line through the mountains, across rivers, and into the Kashmir Valley.

Work on the USBRL began in phases. Over the years, engineers laid down kilometres of track, blasted tunnels through stubborn rock, and built dozens of bridges and viaducts across smaller rivers and valleys.

Bit by bit, stations came up, tunnels broke through, and trains began running on completed sections.

But even as the project moved forward, one section remained untouched for years. Not because it was forgotten — but because it was the hardest of them all. The stretch between Katra and Banihal… where the terrain turns brutal.

And right in the middle of that stretch? The Chenab River gorge.

Here, the river doesn’t just flow — it slices deep into the mountains, carving a gorge nearly 360 metres deep. To give you an idea, that’s taller than the Eiffel Tower.

And building a railway across that, across roughly half a kilometer? It was like staring into an unwritten chapter of engineering history.

There was no feasible way around it. Every metre of rail laid, every tunnel bored, every other bridge constructed — all converged on this single, unavoidable crossing.

Problems

But it wasn’t just the sheer, mind-boggling depth that made this site so difficult. It threw every possible natural obstacle at the engineers.

- The geology here is incredibly complex and volatile. The entire region lies in an active seismic zone, meaning earthquakes are a very real threat.

- The rock here is fractured, unpredictable, and prone to landslides. Building foundations strong enough to stand for over a century in such unpredictable ground was a monumental task.

- Then there’s the weather. This region experiences extreme temperature swings, from intensely hot summers to brutal sub-zero winters.

- And the winds? They can whip through that gorge at speeds of up to 266 kilometres per hour – strong enough to derail a train if not accounted for. Any structure here would need to be incredibly robust.

- And finally, the sheer remoteness of the location. Getting heavy machinery, thousands of tonnes of steel, and countless workers to this isolated spot, high in the mountains, was a logistical nightmare in itself.

Well, in fact there was one more thing.

This bridge lies in a geo-politically sensitive region — not far from the India–Pakistan border. In the unfortunate event of a conflict, such a vital artery could quickly become a strategic target. So, the bridge had to be designed not just to survive nature — but also sabotage or enemy attack.

So the Big question was : What kind of bridge could even survive here?

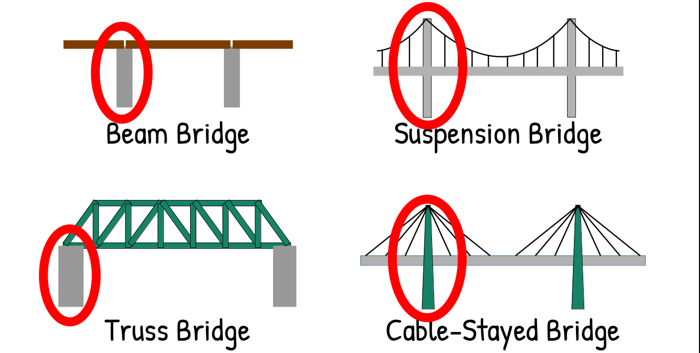

Engineers explored all kinds of options available to them, meticulously studying every possibility: from the solid beam bridge and the interwoven truss bridge, to the elegant suspension bridge and the modern cable-stayed bridge.

But nearly all of them shared one fatal flaw: they would have required, immensely massive support piers or exceptionally tall pylons.

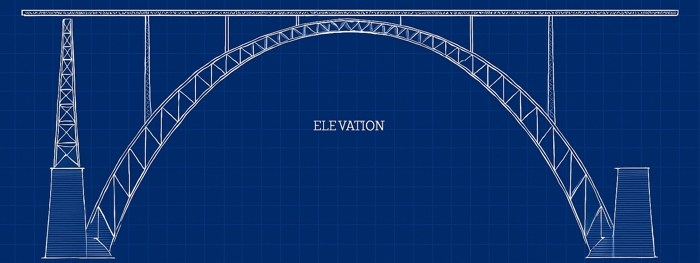

So, the engineers turned to a different, ancient, yet incredibly powerful structural form: the ARCH Bridge.

Why an ARCH?

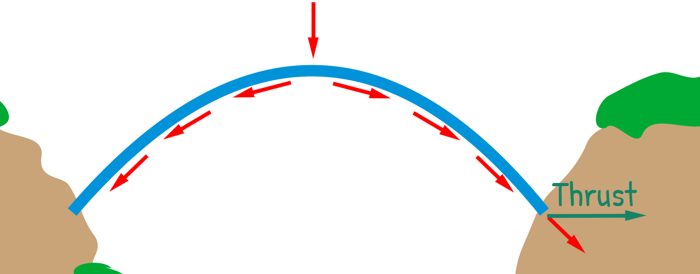

Well, an ARCH is a natural marvel of efficiency. Imagine placing weight on the top of an ARCH. It efficiently channels that downward force along its curve, converting a significant portion of it into a powerful outward push, also called thrust, at its base. This outward force then gets transferred into the sides of the gorge, right where the ARCH touches the mountains.

That’s the key: the ARCH doesn’t need any support in the middle of the gorge. No tall pylons. No vulnerable piers. Instead, its entire weight is transferred into massive, reinforced foundation blocks, called abutments, built into the rocky walls on both sides.

But there was a problem.

The gorge walls, which were supposed to hold up the entire structure, were not made of solid rock. They were fractured, layered, and geologically unstable.

But the engineers, as always, had an idea. And so, the extraordinary construction of the Chenab River ARCH Bridge began.

Engineers began by creating a stable foundation for the bridge. They basically employed three main techniques to stabilize the fractured rock wall.

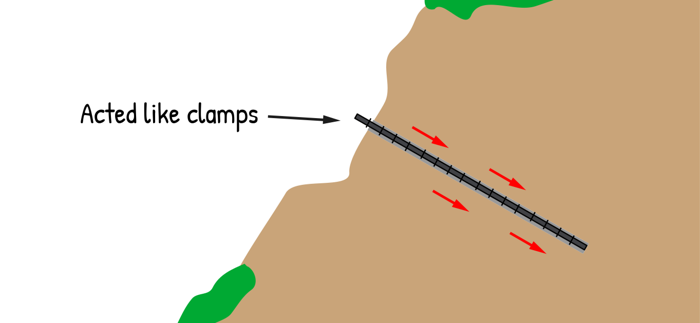

- First, they used rock bolting and anchoring. Engineers drilled deep into the fractured rock — sometimes up to 30 meters — and inserted high-strength steel rods. These rods were stretched so they were in tension, and then permanently grouted in place. Once released, they acted like powerful clamps, pulling loose layers of rock together and making the entire rock mass significantly stronger.

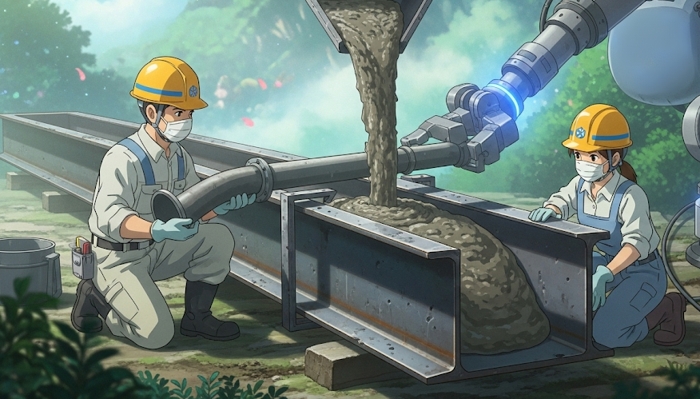

- Second, they implemented Grouting. This involved injecting a special cement-based mixture, known as grout, under high pressure into every tiny crack and fissure within the rock. This grout fills all the voids, binding the fractured rock together into a far denser, stronger, and more unified block.

- Third, for the exposed surfaces, they applied layers of steel mesh and then sprayed them with a special concrete, applied at high velocity, called shotcrete. This created a protective skin, preventing further erosion and weathering.

But wait — did you wonder how engineers even got materials and machinery to a near-vertical gorge face, hundreds of meters above the river?

That, too, was one of the major challenges they faced. Before any actual construction could begin, they had to solve this basic problem of access.

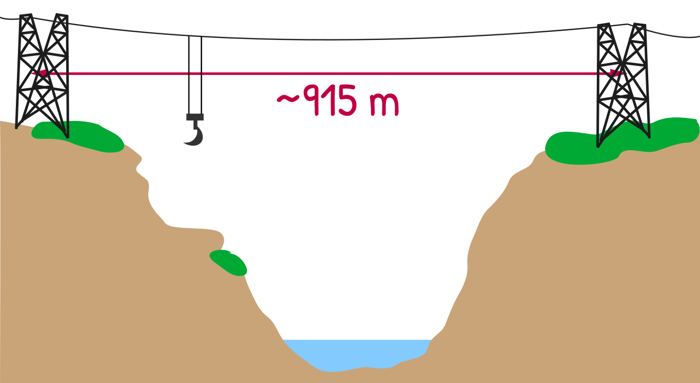

To solve this, they installed a temporary aerial cable crane system across the gorge — spanning nearly 915 metres. This cable crane became the site’s logistical lifeline, delivering everything from rock anchors and grout to rebar, scaffolding, and formwork.

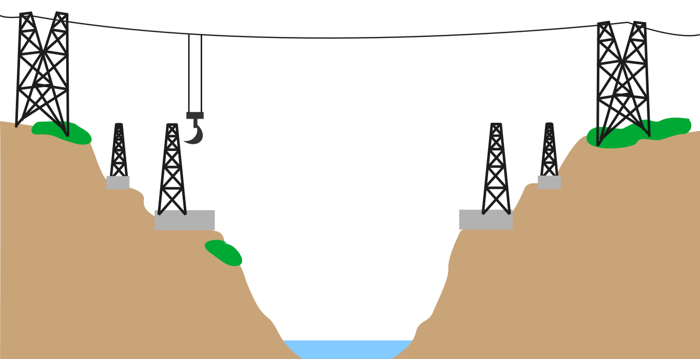

Once the gorge walls were stabilized, the next step was to build the abutments — the massive foundation blocks at either end of the ARCH. These aren’t just supports; they’re the points that absorb the enormous outward thrust of the ARCH and transfer it deep into the mountain.

To achieve this, engineers excavated large pits into the strengthened sides of the gorge. Dense cages of steel rebar were meticulously assembled inside, forming a rigid skeletal framework. Then, using high-pressure pumps and pipelines, high-strength concrete was poured layer by layer into these forms — creating the stable foundations the ARCH and other piers would eventually rest upon.

Next, engineers constructed a series of tall, straight vertical steel piers rising from the abutment zones. They were built first because they had a crucial job to do during construction of the ARCH.

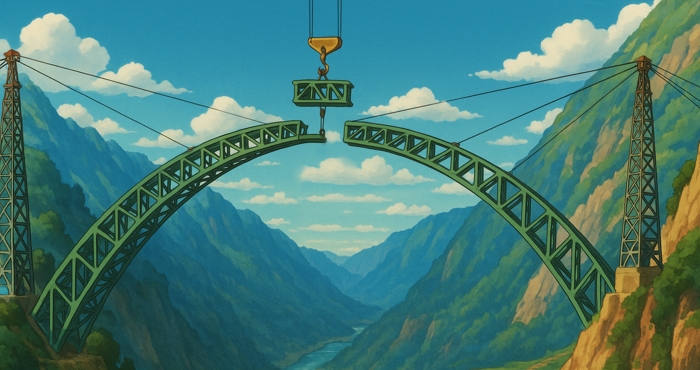

Now the time had arrived to build the ARCH itself. But how do you build something so immense, high in the air, with no support from below?

For this, engineers turned to a method called cantilever construction. They started building the ARCH outward from both sides — little by little — until the two halves would finally meet in the middle.

From both ends, prefabricated steel truss segments were lifted using the cable crane system and assembled section by section. Some of these sections weighed more than 80 tonnes. Once in place, they were held by temporary stay cables anchored to the previously erected piers and to the slopes above.

Each section had to be perfectly aligned, then welded or bolted with incredible precision.

For nearly five years, these two halves of the ARCH slowly crept toward each other.

And finally, on April 5, 2021, the final segment was inserted at the crown. The two ends locked together — and the structural ARCH was complete.

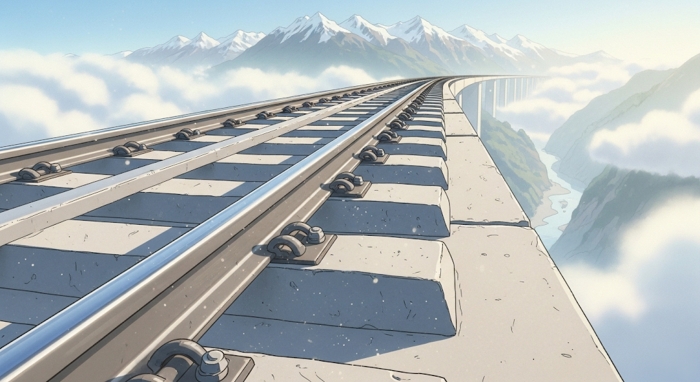

In the next phase, vertical steel members called spandrel columns were installed, followed by the bridge deck itself. Finally, the railway track was laid atop this platform.

With that, a 1,315-meter-long bridge — featuring an iconic 467-meter main ARCH span, built with an incredible 30,000 tonnes of steel and anchored by 66,000 cubic meters of high-strength concrete, and that cost around ₹1,486 Crore or nearly $180 million US dollars — was finally ready. An idea once thought impossible, now stood in solid steel.

But here’s what makes it even more extraordinary…

The Chenab Bridge wasn’t just built to stand tall — it was built to survive the unthinkable.

The steel ARCH itself isn’t hollow; its massive ribs are filled with concrete inside, giving it enormous extra strength, enhanced vibration damping capacity, and significantly boosting its resilience against extreme forces like blasts or fire.

And the entire structure was designed with redundancy, meaning if one component fails, others can carry the load and bridge will be still safe and operational.

Even the paint isn’t ordinary — it’s a special corrosion-resistant coating developed to last 15 to 20 years, shielding the steel from the extreme Himalayan weather.

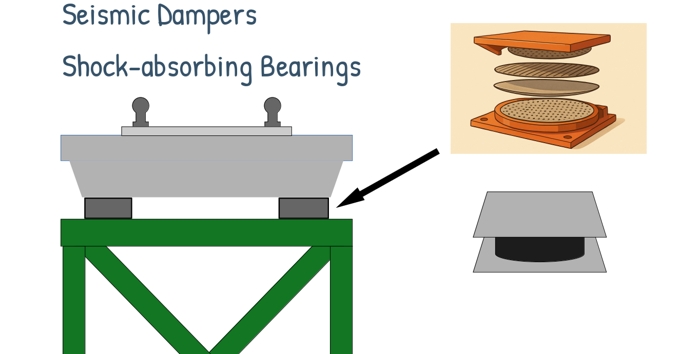

Also the region lies in Seismic Zone V — the highest-risk earthquake zone in India. So, the bridge uses seismic dampers and shock-absorbing bearings to handle vibrations. Including that, the ARCH shape itself helps distribute loads more efficiently, naturally improving earthquake resilience.

And for the railway track itself, they employed a modern zero-ballast system. This means there’s no traditional ballast or crushed stones underneath; instead, the tracks are directly fastened to the concrete deck, offering superior stability, reduced maintenance, and enhanced safety on this critical high-speed link.

But before any train could ever cross it, the Chenab Rail Bridge had to prove itself.

Engineers carried out an intense series of tests — because a structure this daring, in a location this harsh, can’t just look strong. It has to perform under real-world stress.

First came the static load tests. Massive weights were placed on different sections of the bridge to simulate the pressure of passing trains — checking for any signs of bending, shifting, or stress.

Then came dynamic load tests, using actual locomotives moving at different speeds to observe how the bridge responded to motion, vibration, and sudden load changes.

And it passed. Every test.

From the foundation bolts to the crown of the ARCH, the bridge held steady. No surprises. No cracks. No weakness.

And on June 6, 2025, the Chenab Rail Bridge officially opened to traffic — completing one of the most ambitious chapters in Indian railway history.

It wasn’t just an engineering achievement. It was a message — that no mountain is too high, no gorge too deep, and no terrain too unforgiving when the will to connect people is stronger than the obstacles that divide them.