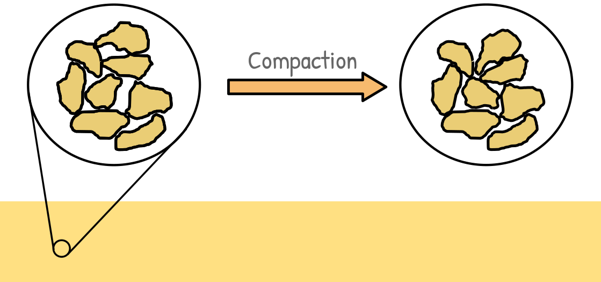

We make the soil base stable and strong Before constructing any structure on it. It is done by increasing soil’s density by decreasing the volume of air voids in it and the process of doing so is called Compaction.

Compaction is measured using Dry Density or Dry Unit weight of Soil. Higher the Dry density, higher is the compaction.

Dry Density of Soil is nothing but density of soil when it is in completely dry state which means no water is present in its pores. So the Dry Density of soil is mass of soil solids only divided by its volume.

Compaction in the field is done using heavy machinery and equipments. These machineries use various methods such as rolling, ramming and vibrations to compact different types of soils.

Generally there are following types of equipments used for the compaction of soil.

Tampers

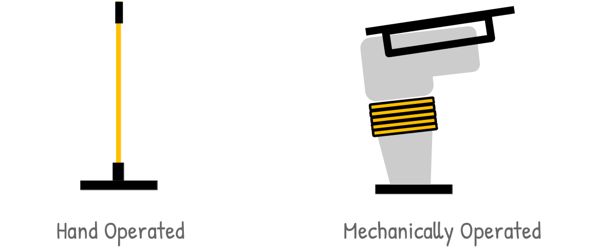

Manually Operated

Mechanically Operated

Rollers

Smooth wheel rollers

Pneumatic tyred rollers

Sheep’s foot roller

Vibratory Compactors

Rollers

Vibrating plate

lets briefly discuss these compaction equipments and methods of compaction.

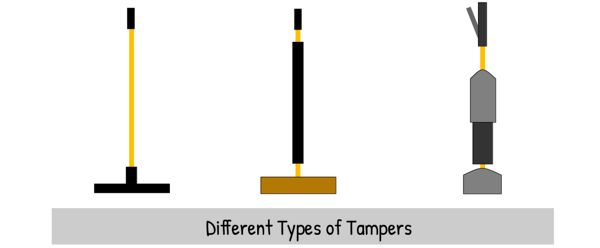

1. Tampers

Tampers can be operated manually by hand or mechanically with the assistance of machinery.

Hand operated tampers consist of a block of heavy metal head of about 3 to 10 kg attached to a long handle. Tampers come in various sizes and shapes, but they typically have a flat or slightly rounded base.

To use a tamper, the operator lifts the heavy head and then drops onto the soil being compacted. This action applies pressure to the material, helping to compress it and reduce void spaces between particles. They are similar in principle to the rammers used in laboratory test.

Mechanical tampers or rammers are compaction tools powered by machinery. These come in a wider range of sizes and weights to about 30 to 1000 kg.

Tampers are often used for compacting small areas or confined spaces where larger compaction equipment cannot reach.

Tampers use:

Tampers can be used for all types of soils. They deliver concentrated force to the soil surface which helps break down larger lumps of soil aggregates of silts and clay and promote better interlocking between soil particles. And for granular soils this focused impact helps to rearrange soil particles, reduce void spaces, and increase soil density.

Tampers may struggle to penetrate and compact soils that are denser. These soils have minimal void spaces and may require more forceful compaction methods to achieve adequate compaction.

Tampers may also encounter difficulty in compacting soils with large rocks or obstructions.

Also tampers are typically manually operated, making them less suitable for compacting deep or thick layers of soil. Compacting large volumes of soil with tampers may be labour-intensive and time-consuming.

Tampers may also not be effective for compacting highly plastic or expansive clays, which have high water retention and swelling properties.

Tampers are useful for smaller projects such as repair of small cracks or potholes of pavement, preparation of ground for building foundation, compaction for walkways, compaction of soil around fence posts, compaction of backfill of drainage system etc.

Then there are for compacting the soils.

2. Rollers

Rollers are heavy construction machines used for compacting soil. Rollers come in different types and sizes, each designed for specific compaction tasks and soil conditions.

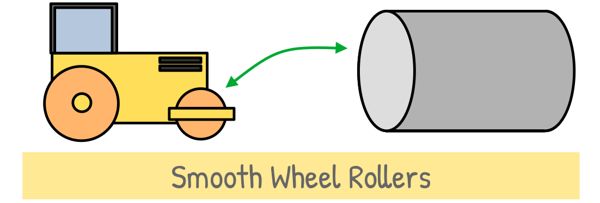

2.1 Smooth wheel rollers

Smooth wheel rollers, also called smooth drum rollers, have a large cylindrical drum with a smooth surface.

These rollers are useful for finishing operations after compaction of fills to provide a smooth surface. They generate low compaction pressure hence they are not effective for compaction of deep layers of soils.

Smooth wheel rollers Use:

Smooth wheel rollers are commonly used for compacting both cohesive and granular soils in construction projects.

But they are not as suitable for soils with high organic content or extremely rocky soils. Also they may not provide sufficient compaction for soils with high plasticity or expansive clays.

Smooth Wheel rollers are useful for large scale earthwork projects such as road construction, highway maintenance, compaction of base for large parking lots, compaction of waste material in landfill construction, compaction of base and sub-base of sports and play grounds etc.

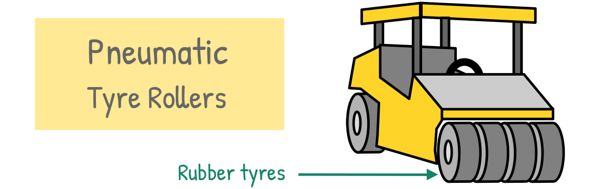

2.2 Pneumatic Tyred rollers

The word “pneumatic” refers to a system that uses air or gas under pressure. In the context of pneumatic tyre rollers, “pneumatic” indicates that the rollers are equipped with rubber tyres that can be filled with air to adjust the tyre pressure.

Unlike smooth drum rollers, which have a single drum, pneumatic tyre rollers have multiple rubber tyres arranged in a grid pattern across the width of the machine. These tyres provide a large contact area with the ground and distribute compaction forces evenly across the surface being compacted.

The roller compacts the soil primarily by kneading action. It helps to break up soil aggregates and achieve greater compaction efficiency. Kneading action, in the context of compaction, refers to the process by which a compaction machine exerts pressure on the soil surface, causing it to deform and reposition. This action is similar to the kneading motion used in baking or cooking, where dough is repeatedly pressed and folded to redistribute its components.

One of the main advantages of pneumatic tyre rollers is their ability to adjust the tyre pressure to suit different soil conditions and compaction requirements.

Pneumatic Tyred rollers USE:

Pneumatic tyred rollers are versatile compaction equipment suitable for both cohesive and granular soils.

Pneumatic Tyred rollers are useful for projects such as compaction of asphalt or bituminous layer in road construction, compaction of concrete surfaces in parking lots, construction of sports courts, playgrounds etc.

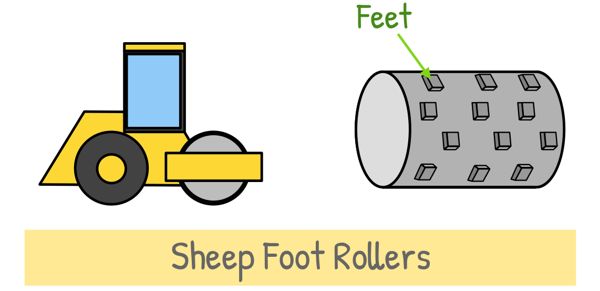

2.3 Sheep’s Foot Rollers

Sheep foot rollers consists of a hollow drum. On its surface it has many small round or rectangular projections know as feet which resemble sheep’s foot.

The feet are projected by about 150 to 250 mm from the drum surface. The weight of the drum can be increased or decreased by filling it partly or fully with water or sand.

A very high contact pressures, ranging from 1400 to 7000 kPa, depending upon the drum size and whether the drum is partly or fully filled, are possible.

These rollers begins by compacting the lower portion of the soil layer. Subsequent passes compact the middle and upper portions of the layer. These rollers do not adequately compact the upper or top portion of the soil layer. Hence, compaction of last layer is generally followed by a few passes of a pneumatic or smooth wheel roller.

Sheep’s foot rollers USE :

Sheep foot rollers are ideal suitable for compacting cohesive soils, particularly clay soils. Cohesive soils like clay tend to have fine particles that can stick together. The feet projections create deep impressions in the soil, breaking up large clumps. This process helps to rearrange soil particles, reducing voids and increasing soil density.

These rollers may also be very effective for fine-grained soils and sands and gravels with more than 20 % fines.

But Sheep foot rollers are not suitable for non-cohesive granular soils, such as pure sands and gravels.

Sheep Foot Rollers are useful for earth work projects such as construction of dams, embankments where high compaction is needed, compaction of sub-grade and sub base layer composed of cohesive soils in the construction of roads and run ways, construction of landfills, pipeline trench backfilling etc.

Now comes the compaction equipments

3. Vibratory Compactors

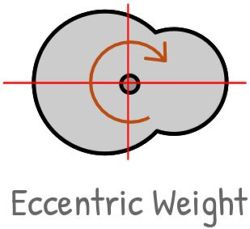

Vibratory compactors, also known as vibratory rollers generate vibrations within the soil during the compaction process. The vibrations are generated through rotation of eccentric weights attached inside the drum.

Vibratory compactors, also known as vibratory rollers generate vibrations within the soil during the compaction process. The vibrations are generated through rotation of eccentric weights attached inside the drum.

The vibrations produced by vibratory rollers sets the soil particles in motion and help them rearrange to reduce void spaces more effectively than static rollers. This enhances compaction efficiency and allows for denser and more uniform compaction of the material.

Such vibrators can be attached to any other rollers, so these compactors are available in a variety of forms such as smooth drums, sheepsfoot drums etc to suit different compaction requirements and soil conditions

.

Another form of a vibratory compactor is a vibrating-plate compactor. They work on similar principle to vibratory rollers. It consists of a flat metal plate mounted on a base with an engine and vibrating mechanism. These are Hand-operated and their effect is limited to small depths. They are used to compact the soils over small areas, which are inaccessible to the large size compaction equipment.

Another form of a vibratory compactor is a vibrating-plate compactor. They work on similar principle to vibratory rollers. It consists of a flat metal plate mounted on a base with an engine and vibrating mechanism. These are Hand-operated and their effect is limited to small depths. They are used to compact the soils over small areas, which are inaccessible to the large size compaction equipment.

Vibratory Compactors USE :

Vibratory compactors are very efficient in compacting granular cohesionless soils such as sand, gravel and crushed stone. These compactors can compact such granular soils to a very high Maximum Dry Density.

Vibratory rollers are all-purpose machines capable of effectively compacting various soil types, including both granular and cohesive soils. However, their efficiency in compacting cohesive soils may be reduced compared to granular soils due to the higher moisture content and stickiness of cohesive soils, which can hamper the penetration of vibrations and require additional passes or alternative compaction methods to achieve the desired density.

Vibratory Rollers are useful for projects such as compaction of base materials, subgrade soils, and asphalt layers in road construction, compaction of base layer in construction of parking lots, driveways, side walk, compaction of waste materials and cover layers in landfill construction etc.

Selection of the equipment and the procedure of compaction depends on the type and properties of the soil to be compacted.

Application of vibrations is the most effective method of compacting granular and cohesionless soils. We can create these vibrations by dropping weights or using hydraulic pulsation.

Even existing loose sand deposits when subjected to vibrations also get densified. But Rolling is the least effective method of compacting cohesionless soil deposits.

For soils containing some amount of cohesive particles, the most effective method of compacting them is to compact them in layers with rollers.

The choice of roller type depends on the plasticity content of the soil. For silts with low plasticity, pneumatic tyred rollers are the preferred option. while, sheepsfoot rollers are better suited for soils with moderate plasticity.

Here is the summarised information into a table of the compaction equipments and types of soil they are suitable to be used upon.